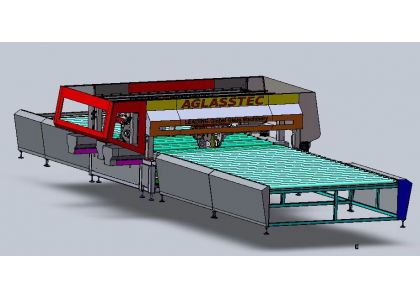

In the realm of glass processing equipment innovation, AGLASSTEC is painstakingly sculpting a remarkable creation that is set to astound the Egyptian market - the FGE - HF2500 - 4 Horizontal Roller Seaming Machine. Currently, while this machine, which embodies innumerable efforts, is still on the production line, its remarkable quality and innovative prowess have already generated significant anticipation.

This FGE - HF2500 - 4 Horizontal Roller Seaming Machine represents the culmination of the ingenuity and inspiration of AGLASSTEC's designers. They have delved deeply into the processing traits and industry challenges associated with insulating architectural glass, door and window glass, clear glass, and Low - E glass. From the initial concept sketches to the meticulous design of every structural facet, they have undergone a multitude of simulations and refinements. The designers have painstakingly contemplated the material and form of the rubber rollers to ensure that they can firmly grip the glass for stable conveyance and also afford the glass the utmost care during edge milling, eradicating any potential for scratching. To surmount the difficulties of film removal and edge sealing for Low - E glass, they have scoured extensive research materials and embarked on dedicated technical investigations, ultimately devising a unique processing module that renders this intricate process highly efficient and precise.

Within the production facility, AGLASSTEC's production technicians have translated the design blueprint into a tangible reality through their exceptional craftsmanship and arduous labor. Each technician resembles an artisan. They meticulously select top-notch materials as if they were choosing the rarest of gems, with the sole intention of constructing a robust and durable equipment foundation. During the assembly phase, they draw upon their wealth of experience and acute tactile sense to assemble each component with unerring accuracy down to the millimeter. Their dexterous hands have adeptly calibrated every parameter of the equipment, spanning from the responsiveness of the fully automated interface operation to the stability of the PLC control system, from the precision of the intelligent and rapid-response servo system to the efficiency of the high-speed edge grinding mechanism, all of which have been subject to their repeated scrutiny. They have remained steadfast day and night on the production line. Confronted with the intricate circuitry wiring and mechanical assembly, they have not faltered in the slightest and have toiled overtime to guarantee the timely and high-quality delivery of the equipment.

Once this FGE - HF2500 - 4 Horizontal Roller Seaming Machine reaches its final form, it will dazzle in Egypt with its state-of-the-art features such as fully automated interface operation, an intelligent computer-governed high-speed and accurate glass transmission system, and a high-speed edge grinding structure. The seamless integration of its automatic glass size detection function and the rubber rod pressure roller wheel positioning system will revolutionize glass processing, making it more intelligent and efficient than ever. Different sizes of glass can be continuously laminated with impeccable diagonal accuracy. Moreover, its formidable compatibility allows it to interface flawlessly with automatic connection machines, automatic horizontal drilling machines, washing machines, tempering furnaces, and other equipment, thereby assembling a comprehensive automatic glass processing production line and emerging as a crucial asset in the domain of insulating architectural glass edge sealing.

The designers and production technicians of AGLASSTEC have bestowed upon the FGE - HF2500 - 4 Horizontal Roller Seaming Machine a distinct essence and value via their dedication and artistry. It is not merely a glass processing apparatus but also a testament to AGLASSTEC's unwavering pursuit of excellence and refinement. In the impending voyage to Egypt, it is poised to initiate an innovation upheaval in the glass processing industry and garner the acclaim and trust of customers worldwide.